-

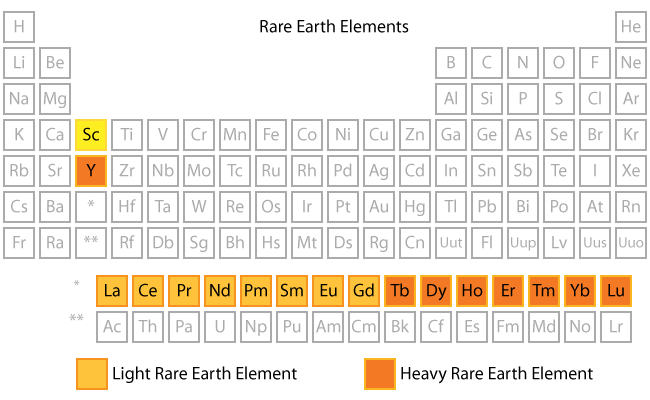

Application of rare earth elements in high temperature alloys

High-temperature alloys are a type of material used in high temperatures and extreme environments. They have excellent high-temperature strength, oxidation resistance, corrosion resistance and other characteristics. They are widely used in aviation, aerospace, energy, chemical industry and other ...Read more -

The development history of high temperature alloys in the UK

The UK is the first country in the world to research and develop high-temperature alloys. British turbine engine technology developed rapidly during World War II, especially the Royal Air Force’s engine development, which made major breakthroughs. In order to meet the requirements for parts...Read more -

The role of alloy elements in high temperature alloys

High-temperature alloys are a type of special alloy materials used in high-temperature environments and are widely used in aviation, aerospace, shipbuilding, petrochemical and other fields. High-temperature alloys have excellent high-temperature strength, high-temperature oxidation resistance, an...Read more -

What is Incoloy 28 material?

INCOLOY 28 is a highly alloyed austenitic stainless steel with excellent corrosion resistance and can resist the erosion of various corrosive media. This article will introduce the performance characteristics, application fields and related technical parameters of INCOLOY 28. Performance characte...Read more -

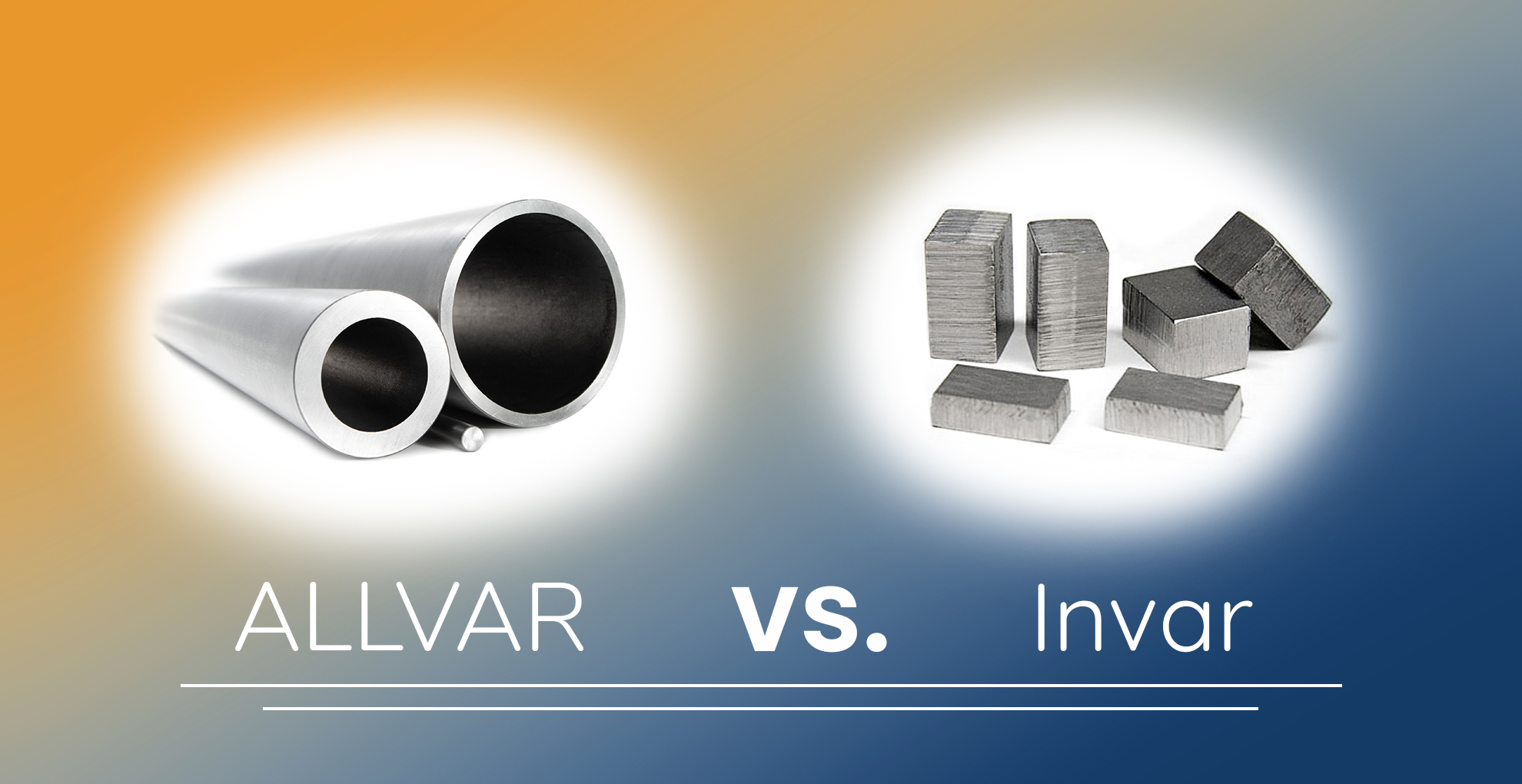

Know more about precision alloy

Precision alloys are a type of alloy materials with special properties, including grades such as Kovar, Invar, Super Invar, Nilo 42, Nilo 48, Nilo 52, Nilo 36, Nilo 50 and Nilo 51. The main characteristics of these alloy materials are low expansion coefficient, high strength, high toughness, high...Read more -

What is Hastelloy C276?

Hastelloy C276 is a solid solution strengthened nickel-molybdenum-chromium alloy containing a small amount of tungsten. Hastelloy C276 exhibits excellent corrosion resistance in various harsh environments and media. Like many other nickel alloys, it is ductile and easy to shape and weld. This all...Read more -

What is meant by super alloys?

Super alloy is a high-performance metal material with excellent high temperature resistance, corrosion resistance, wear resistance and high strength. These alloys are mainly composed of nickel, chromium, cobalt, tungsten, molybdenum, iron and other elements, and their properties are better than t...Read more -

The role of Hf in high temperature alloys

High-temperature alloys are a type of alloy materials with excellent properties at high temperatures and are widely used in aviation, aerospace, energy and other fields. Adding an appropriate amount of Hf to cast and deformed high-temperature alloys can strengthen and toughen the alloy by produci...Read more -

Application of nickel-based high-temperature alloys in aeroengines

The high thrust-to-weight ratio requirements of modern aeroengines have made the service conditions of hot-end component materials increasingly stringent. Nickel-based superalloys are widely used in hot-end components such as blades of aeroengines due to their excellent high-temperature mechanica...Read more -

Research progress on composition design of single crystal superalloys for aerospace engines

With the development of aerospace engines, the requirements for high-temperature performance and service life of materials are getting higher and higher. Nickel-based single crystal superalloys are widely used in aerospace engines due to their excellent high-temperature properties and oxidation r...Read more -

Research on Nickel-based Casting Superalloys and Heat Treatment Processes

With the development of science and technology, the industrial production requirements of aerospace, automobile and other industries continue to increase. In order to adapt to the overall industrial production requirements for high-temperature components in gas turbines, turbine blade casings and...Read more -

What are the manufacturing processes for high-temperature alloys?

The manufacturing process of high-temperature alloys usually includes the following steps: 1. Raw material preparation. The raw materials for high-temperature alloys are usually metal elements, alloy powders and other additives. These raw materials need to be mixed, crushed, screened and other pr...Read more